Ok Elco - perhaps my newbie-ness.

I assumed the gcode included all codes/operations and the print controller uses it. But, The Advanced portion of the Print Settings in the controller took precedence and they did not have M106 on/off steps:

;-------slice start--------

;PROJECT($SliceNr < $BtmLyrs?$ExTimeBottom:$ExTime)

G1 Z(-1 * $ZLiftDistance * $ZDir) F($SliceNr < $BtmLyrs?$ZBottomSpeed:$ZLiftSpeed)

G1 Z(($ZLiftDistance-$LayerThickness) * $ZDir) F$ZRetractSpeed

;DELAY$AutoDelay

;-------slice end--------

So, it works with adding M106 on/off into that advanced setting (above) in the controller.

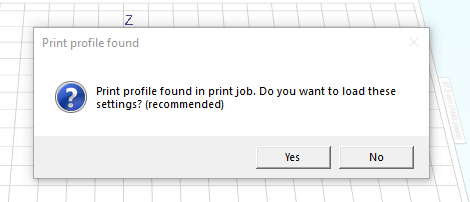

Given this, how does this work with the printer/resin profile in your slicer which have bottom thickness and layer timings? There are also layer thickness and timings in the print controller. Do these in the controller take precedence as well? I’d rather see it driven by the slicer as I create and choose a resin profile per project and adjust in the controller as needed if the outcome is not as expected/needs adjustment.

Thanks and Regards,

Kent