3 Days using Formware. Very impressed.

Supports are sticking to build plate, needed to slightly enlarge them.

Experimenting with a cowgirl truck driver, from T’verse.

Printing with bum close to build plae, laying on her back.

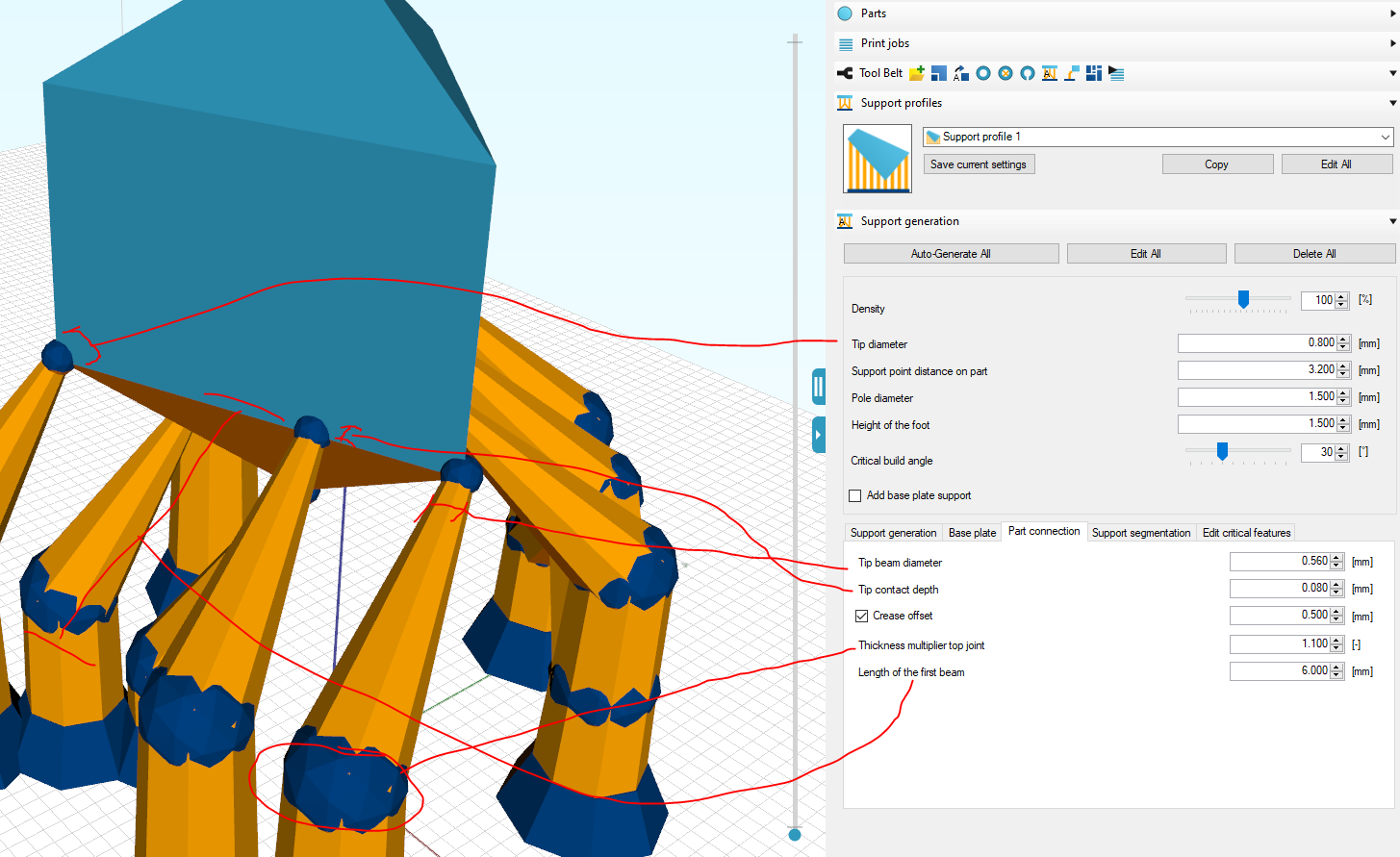

I’ve tried different combinations of support contacts, but the model pulls off the supports and sticks to the FEP. FEP is in excellant condition.

Tried numerous settings, to the point of pulling out what hair I have left.

What settings can anyone suggest, to try first, please.

Also how can I force auto generated supports to only go to the build plate and not the model?

I’ve used chitubox for a year, most similar prints have stuck to the build plate, over 95%.

Dave