Hi, any idea why 2 slicers in default have so much different result in creating support structure?

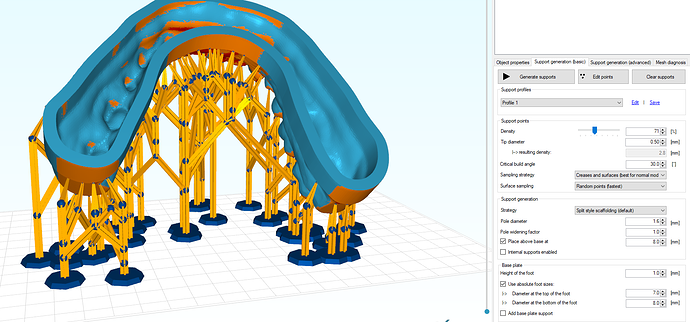

I am comparing UNIZ slicer vs Formware slicer, same model, almost same orientation ( but dues not matter too much in some degree difference )

Result is from new UNIZ slicer where it looks like it supports only the lowes unsupported isles where formware supports all places over critical build angle.

Comparison of results is here ( screenshots )

I can share the STL files with support structure and model, if usefull for evaluation.