Hello

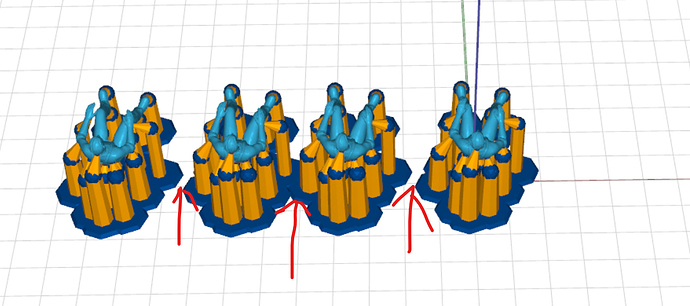

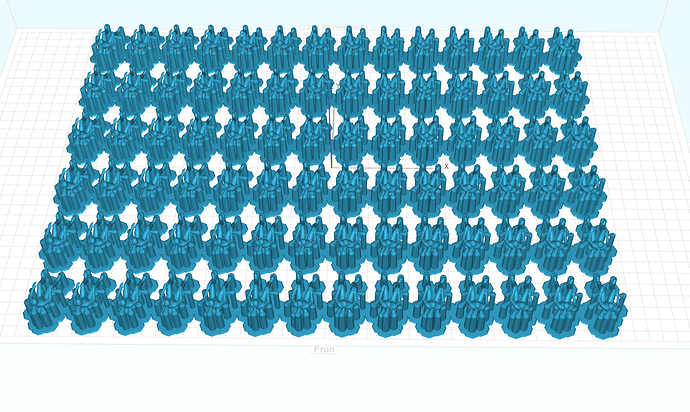

I tried to print this figurine now several times, and the part is always breaking of the support structure. It does

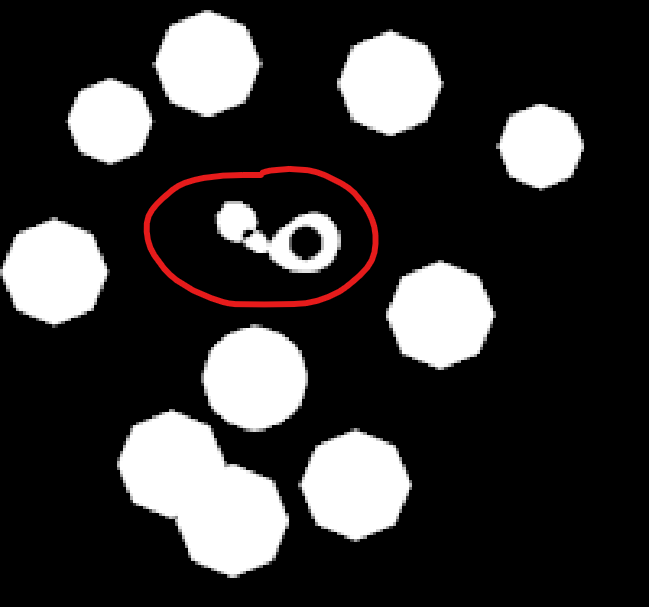

not even print on the supports. So I looked into the sliced pictures, and found the following.

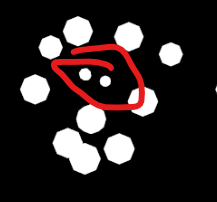

The support tips are hollowed in the middle. That clearly explaines why the part will not print on the supports.

Is this intentional? How can this be changed or skipped?

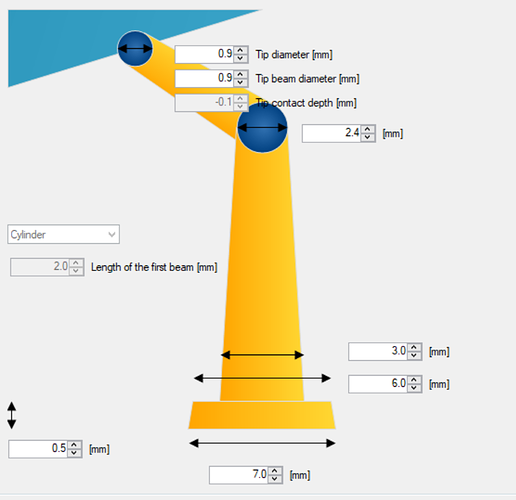

Here my settings: (it is a flexible material, so I need tougher foot structure)

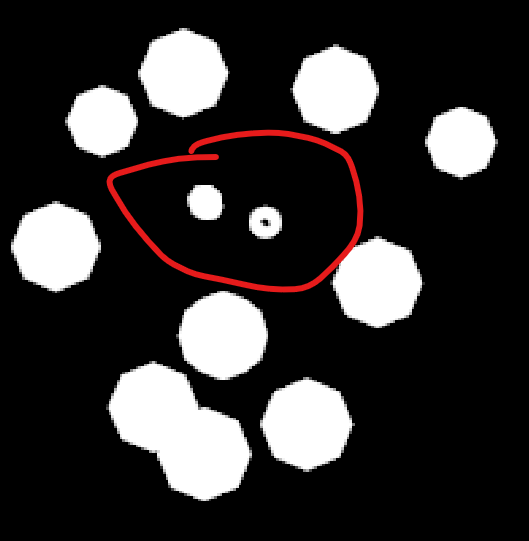

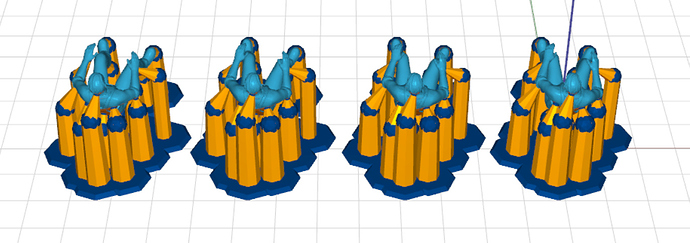

We´ll have a look at this two support tips:

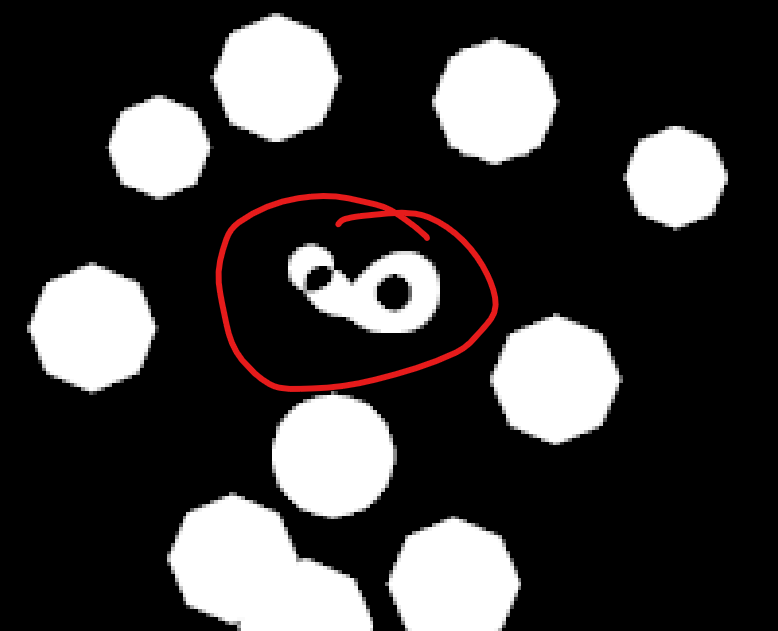

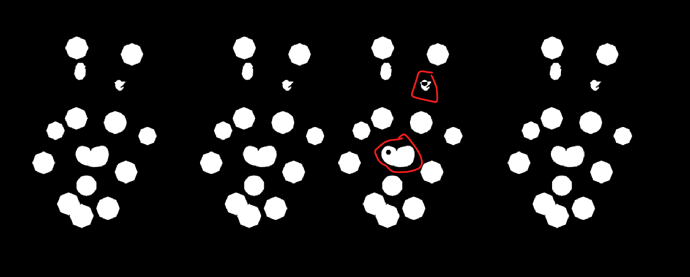

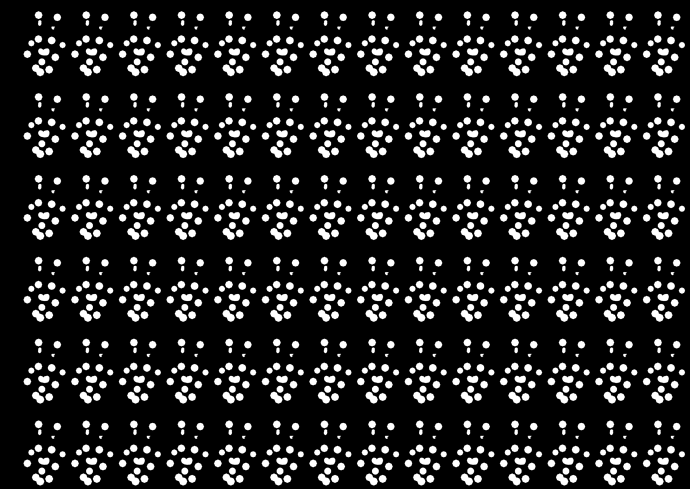

Here some views of the slices:

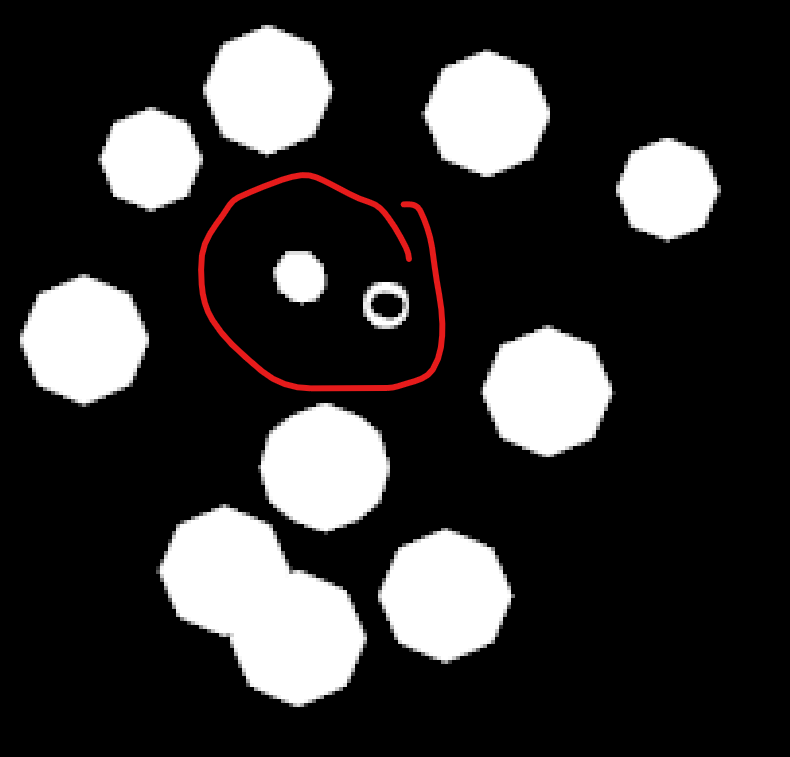

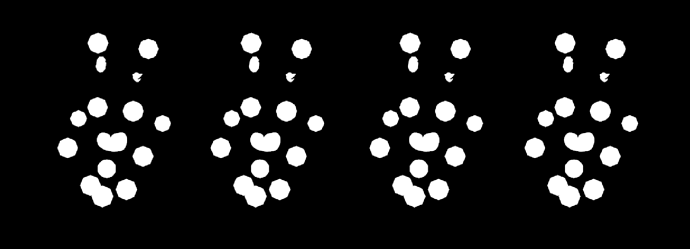

next layer:

next layer:

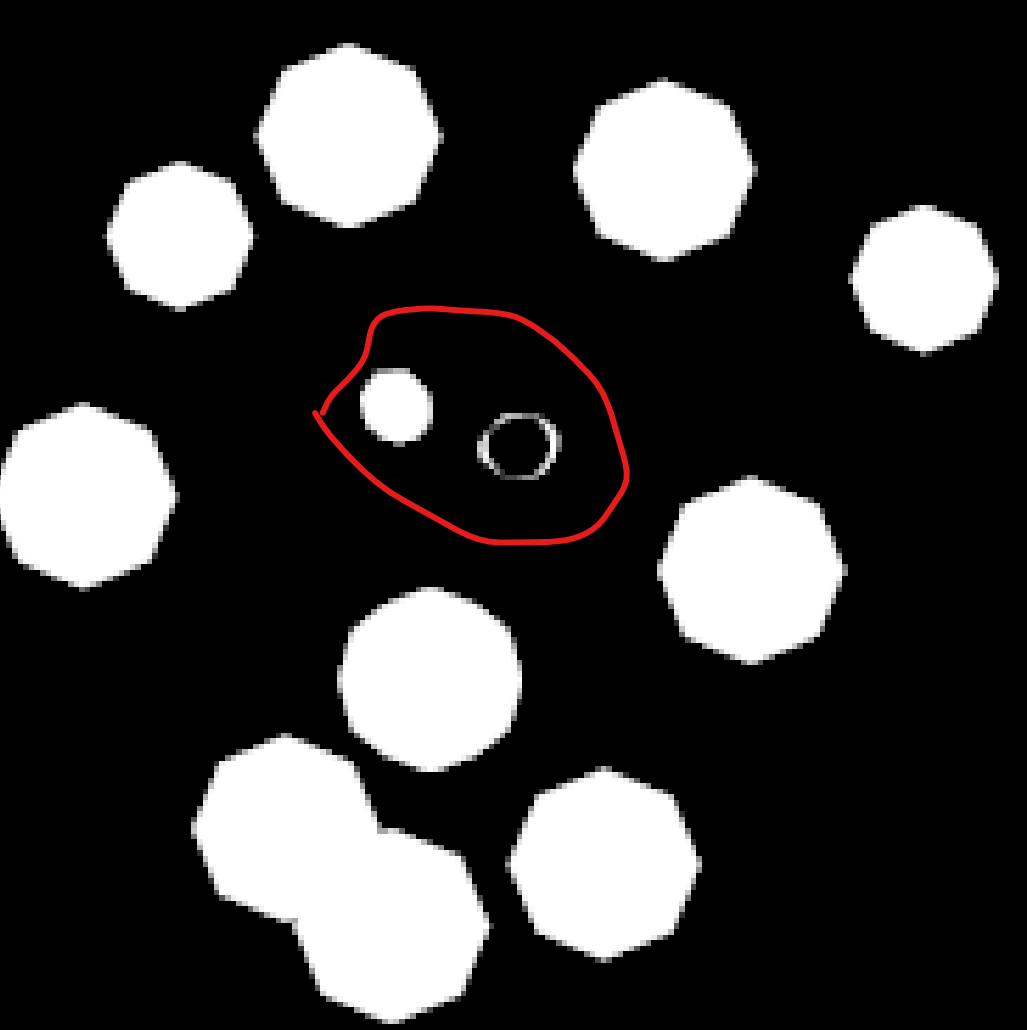

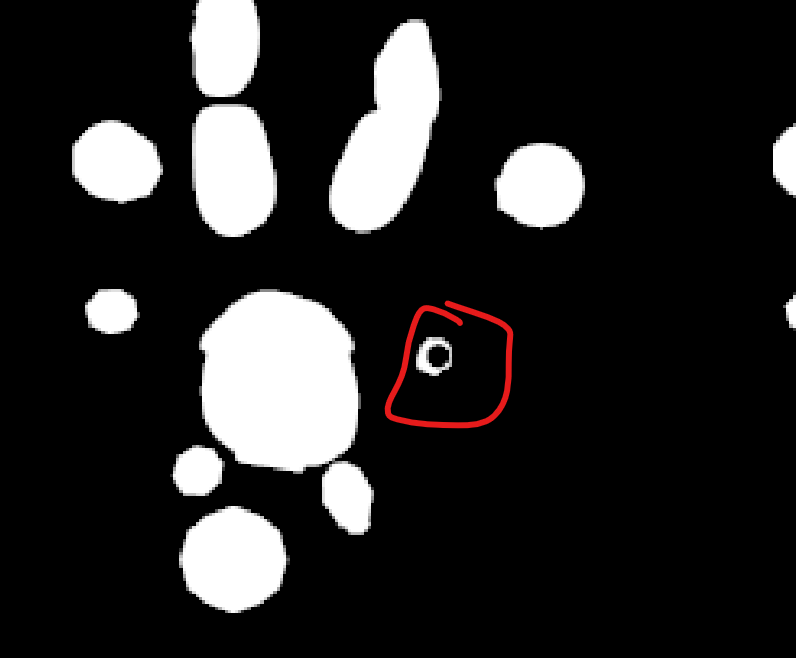

two layers later, almost gone:

three layers later, model starts to rise around the hollow support:

next support starts to hollow:

other supports doing the same, enough now:

Is that a normal behavior?

Best regards, Chris