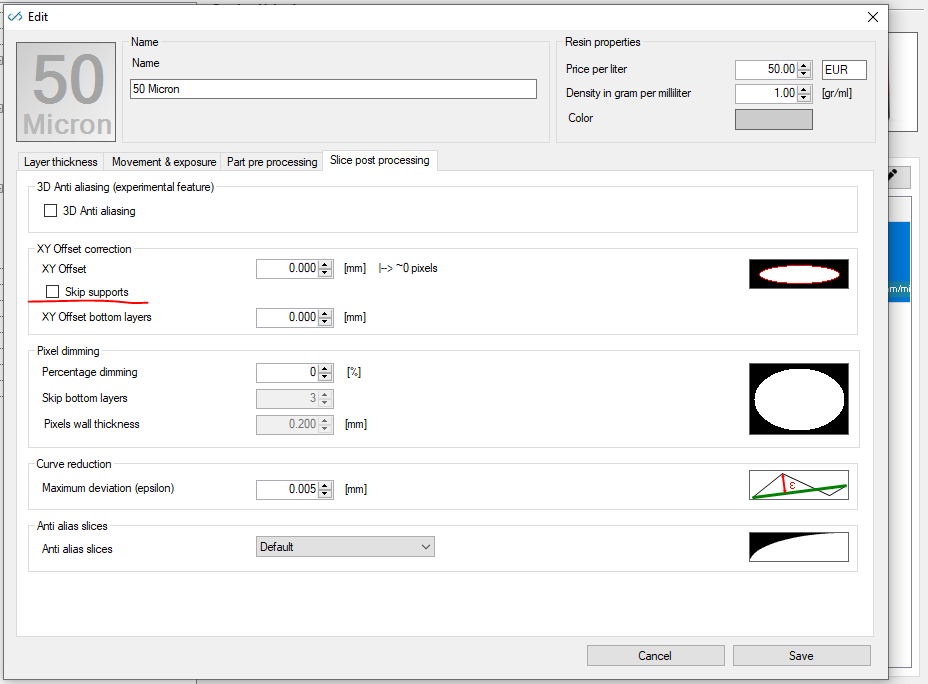

Can a toggle be introduced to either enable or disable the consideration of support features being influenced by slice post processing parameters?

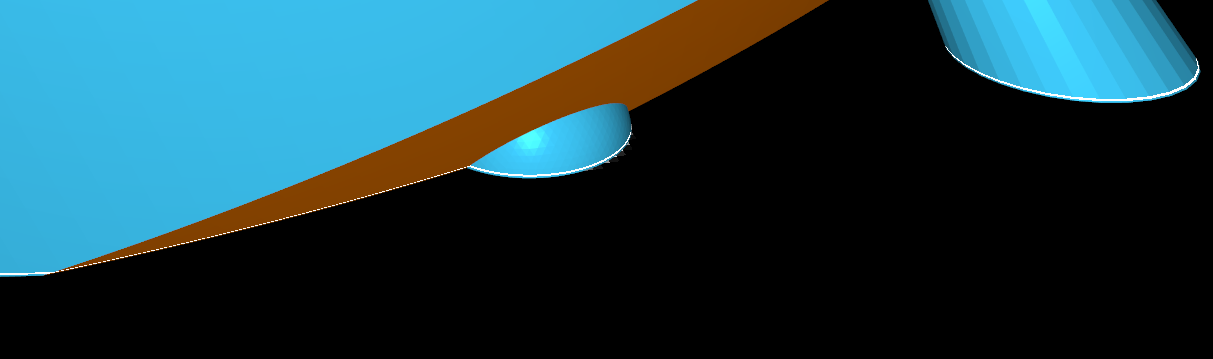

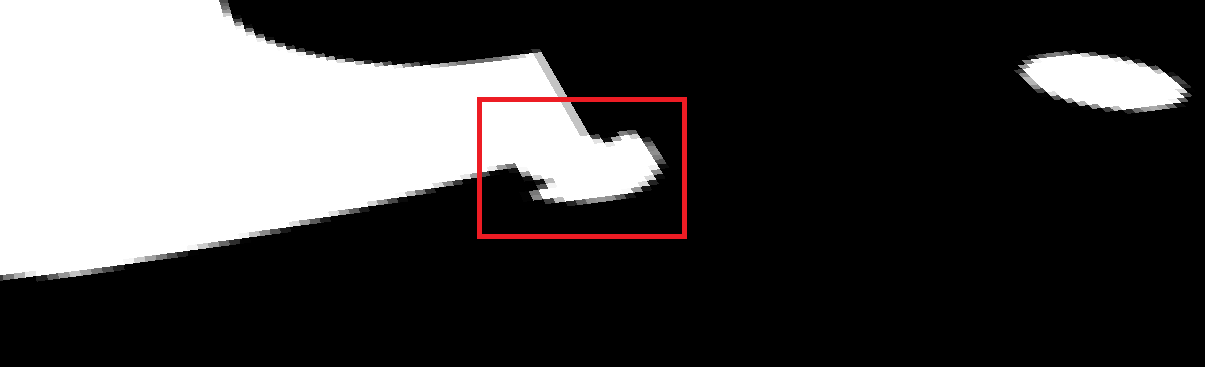

Attempting to use a -0.1mm XY Offset to get my part dimensionally accurate. The XY tolerance has a negative influence on my supports, as they reduce the first beam contact diameter. Artificially increasing the beam diameter to compensate will not work in my situation.

Please let me know if there is a workaround to this issue.

…

…