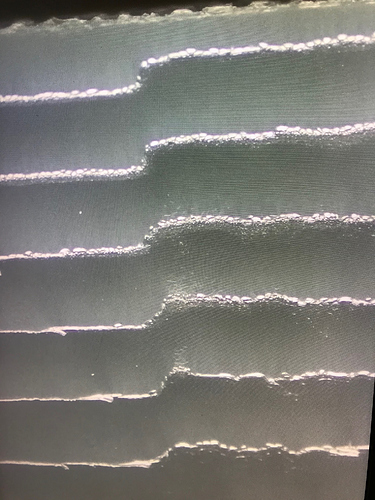

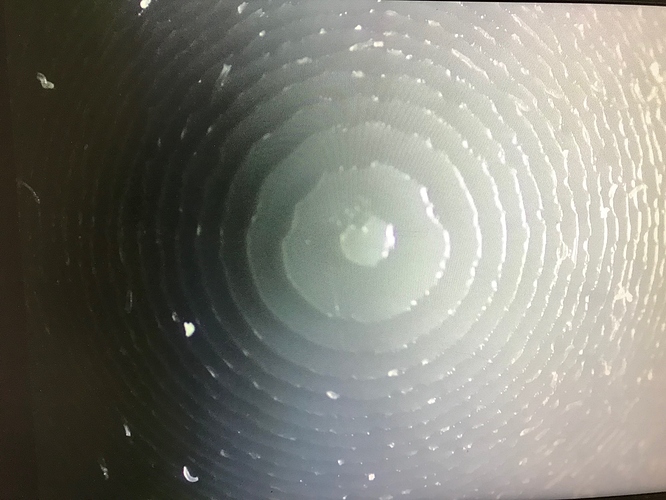

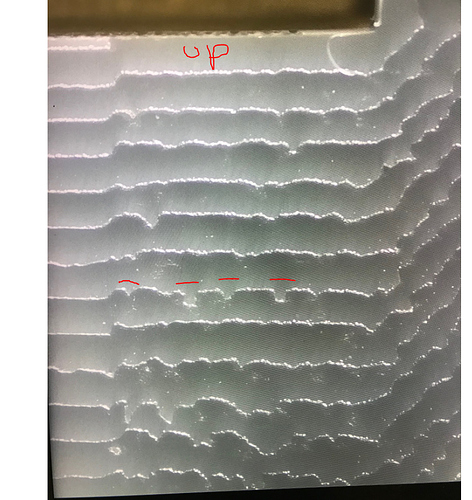

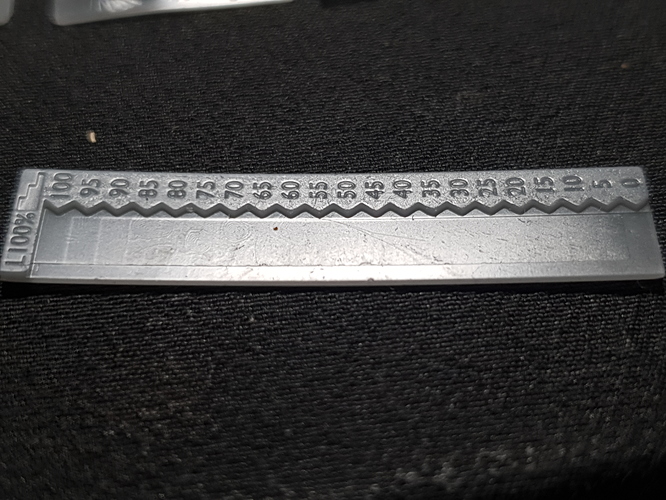

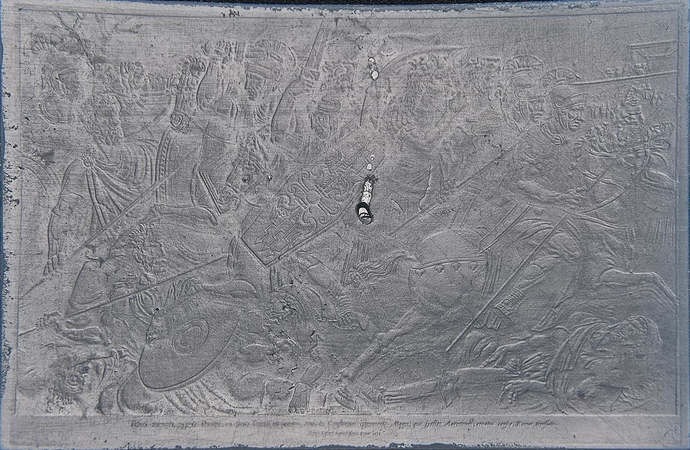

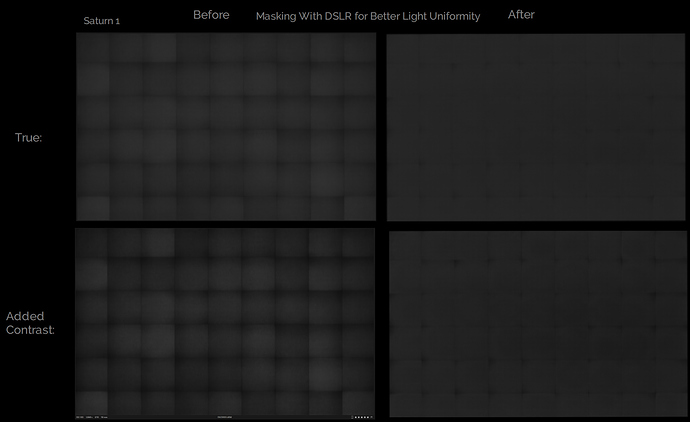

Well the most unique thing about how I did it is that I’m not using a DLP printer like you or the ember team, it’s just an old saturn 1 with a thick screen protector so the bloom is like 4-7 degrees Minimum. This isnt ideal because it means the light could be less concentrated by the time it reaches the last layer as compared to when it passes the fep and first touches resin. Most people even very knowledgeable people in the resin printing community think 3D AA can only be done on industrial printers, they assume that on consumer printers the resin always cures from the fep up but it just isn’t true unless the layer height is too high, I can do 50um with pigmented and clear but at 100um clear it cured from the fep up, I haven’t tried 100um with pigmented yet but I’m sure it would be worse.

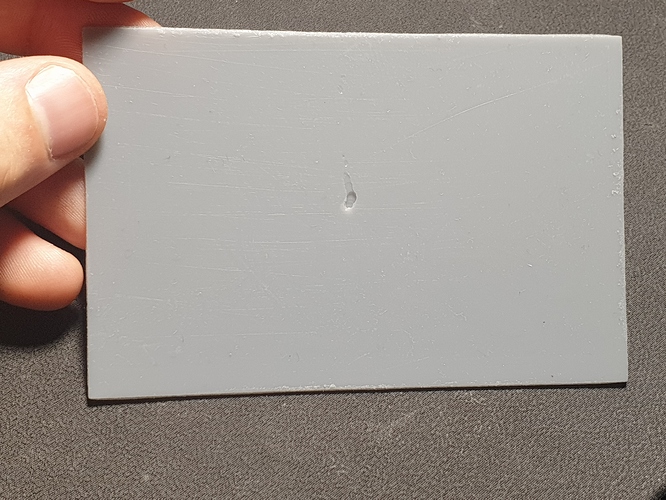

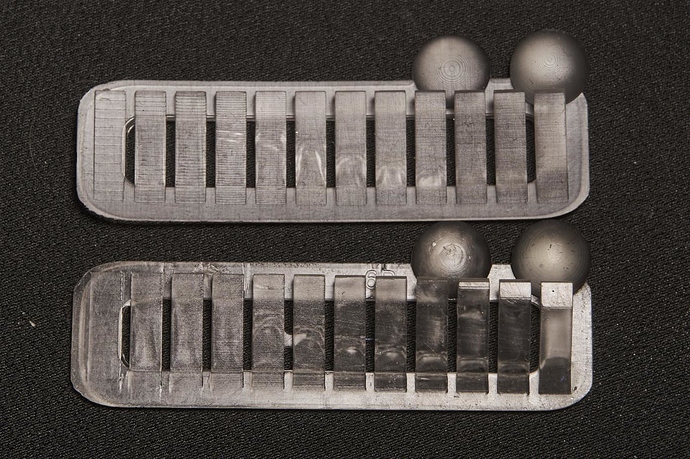

The monkey is pigmented resin, the reason it looks perfectly smooth despite me only getting perfectly smooth results with clear resin thus far is that the monkey is printed on one 50um layer! The pigmented resin I’m testing with atm is 3DMaterials superfast grey, I’m going to test either elegoo space grey 8k or ST fast grey abs like next.

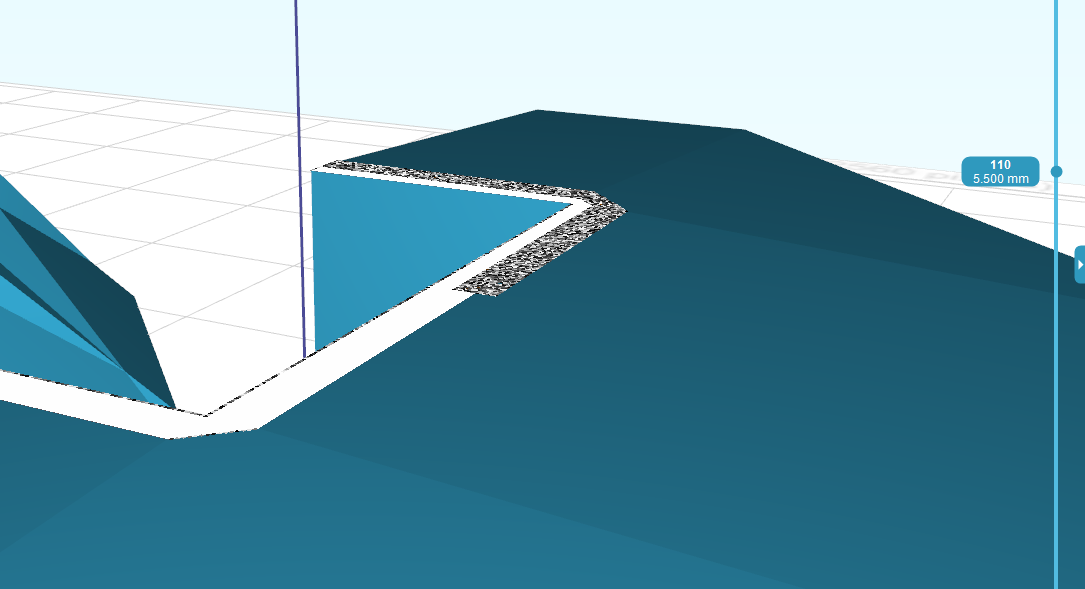

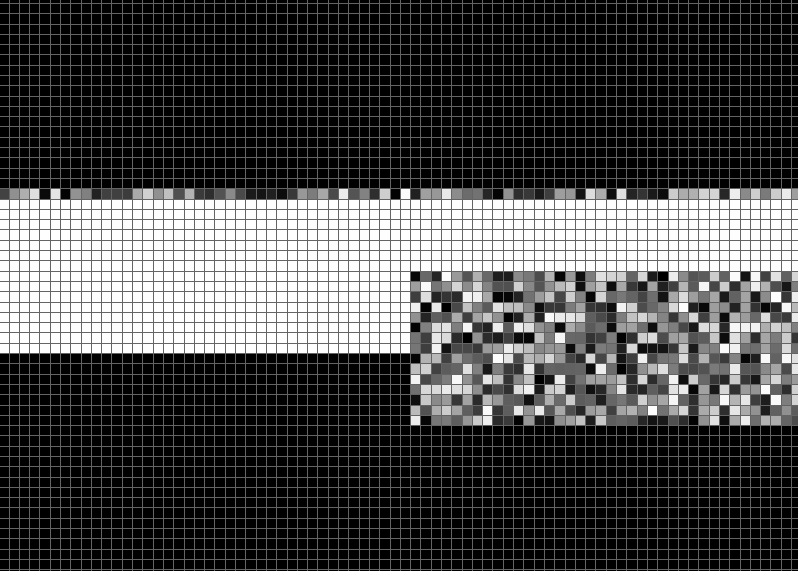

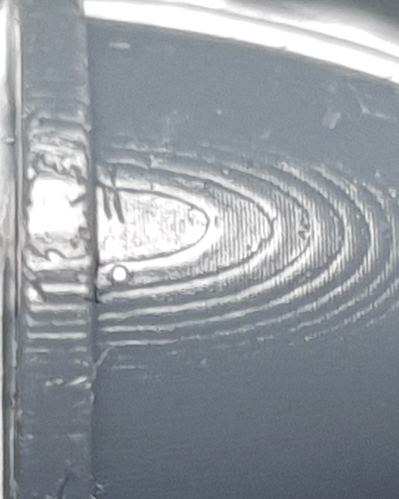

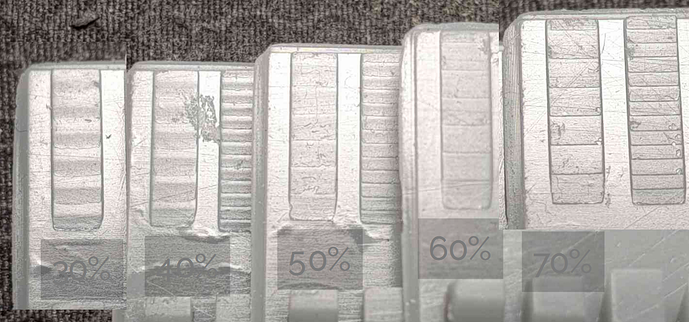

For the gradient modifications I firstly get a good 0.0-1.0 value gradient and then apply a compensation curve, I was using my own curve but now use one more similar to the one showed in the long ember video, except they do it all in one curve. I split it into three, firstly the curve compensation to fix how resin doesn’t cure uniformly, gradients cna look bumped when they shouldn’t be. Then I apply the upper grey offset, usually with a proper exposure 90% can still produce a full height layer so I squash down the highest value of the gradient so that the gradient starts actually going down on height when it should rather than remaining at full height until it gets to 20% into the gradient. Then I do the same for the lower grey offset because of course resin doesn’t start to cure until a specific point which from my tests seems to be about 60% at 50um and 40% at 30um, this of course varies with printers and resins but when properly exposed it doesn’t vary as much as would think at least from my limited testing.

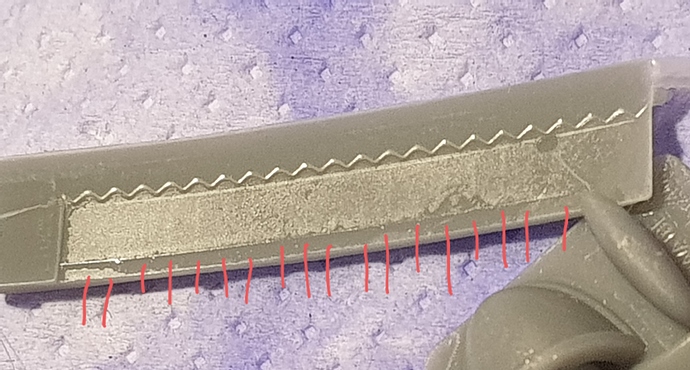

Also I have all the major variables like upper and lower grey offsets and compensation curve strength and layer overlap etc hooked up so that I can vary them per model to have dozens of tests print at once. And I can also do things like use a normal pass to do different settings for different angles, eg when angles get steeper the resin doesn’t produce tiny gradients, no just acts like normal XY AA where the edge just moves about so a different curve to account for the higher bloom or a wider gradient (larger layer overlap) or a lower upper and higher grey offset etc could be preferable, I can adjust all these settings dynamically with a normal map.