Formlab can slice with different layer height,is it planned to support this feature for DLP and Gcode slice?

Variable Z height

To be honest we actually had it in there for a while (2years) that you could set various segments of layer thicknesses.

But we discussed it here and figured it would be way better to ‘auto-detect’ those segments.

Question is only how to find a smart trick to play this…

So yes; it’s already in there in code.

Just not working the way we want.

2 doubts i have

1.thicker layers means you have to expose longer; does this really yield faster print times?

2.if you want thicker layers to speed up your supports at the lower end; why did you make them that long in the first place? Then probably your entire part should be the same layer thickness?

For my need (Moai SLA),exposure is set by laser speed (depend of profile).Sometime parts are more defined in some area and not at another.I just would have multiple layer (with associated profile) as simplify3D do (multi porcess

Let’s assume just 2 layer thicknesses. 30um at 7s and 50um at 8s. We have a model that is 30mm tall. With variable height say we can slice 15mm at 50um.

15mm @ 30um = 3500s

15mm @ 50um = 2400s

total time with variable height 5900s

30mm @ 30um = 7000s

there are certainly situations where it would take the same (if not longer) but I would say on average you should be able to shave quite some print time.

This is a good video about the concept. The algo is very simple and open source

yes it’s on the list.

however; a big remark i have with this kind of functions is that it only works with simple geometrical shapes.

For a big part of our market; filligrain jewelery and dental there is so much curvature all over the models that it doesn’t help…

My scenario would have been if my print is elevated off the bed, I would print the supports at a larger slice, then switch over to the thinner slice when I get to the actual object. It would shave some time off the print, which always helps.

So I would be happy where the thicker slices were the first ‘n’ layers, then switch to the desired slice thickness.

Following. Dental models consist of base with supports (simple geometry) and teeth (complicated geometry) if printed flat.

Hi,

Yes there is. Algoritm is written couple weeks back; I just need to find a good way of inserting it in the slice process in a way that is managable.

We’re rewriting the slice processor to optimize it further for speed and some other new features. So it will be incorporated there as well.

Couple of weeks is my best guess.

Elco

Hello Elco,

Do you a further update regarding this feature?

Many thanks in advance.

Best,

MarkCK

Yes. It’s released since V1040, with some bug fixes and improvements in V1042.

It’s documented in the documentation as well.

But i’ll summarize it here for the ones interested.

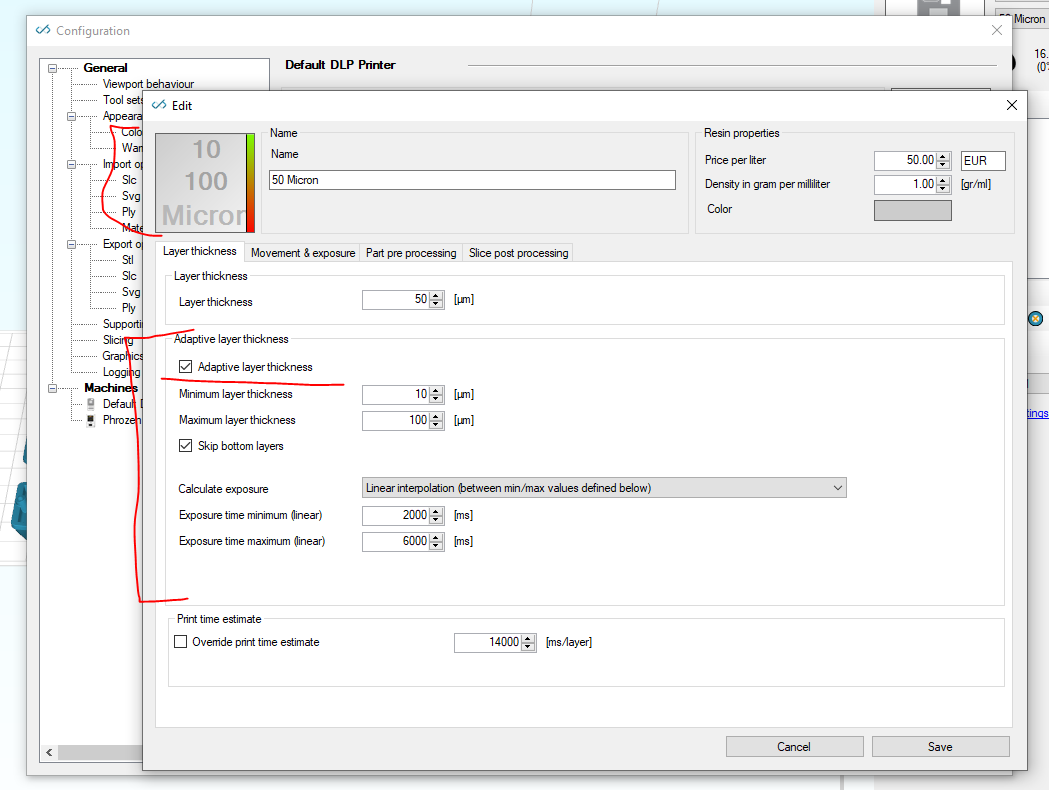

You can activate it per print profile in the config:

Settings are documented and i think most are self explanatory.

For the exposure time there are 3 settings.

- fix all to same value (default exposure value from movement tab)

- linear interpolate between 2 given values

- use exponential calculation (you need to know your machine for this and exact resin specs.)

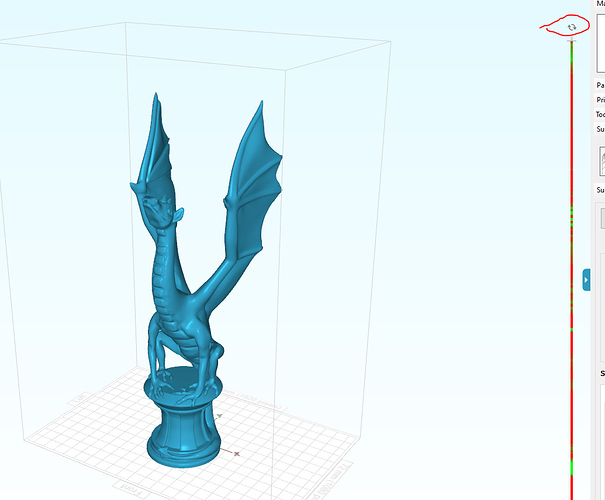

In the 3d view you will receive a small refresh icon on top of the slice bar.

Upon selecting a profile with adaptive strategy it will update once. After that you have to manually do it as it would be to annoying otherwise. Before slicing it automatically updates it.

I still have to add some functionality to manually fix a number of slices to a fixed height.

It works for every type of export and every file format it was able to write a layer height/exposure into the layer info. Whether it works on specific file formats i have my doubts and it’s to be tested. According to CTB it should work on the CTB SDK exported format if the machine has the latest firmware. I think also on photonworkshop files it should be possible to use it with the latest firmware.

For machines using gcode it should of course be no problem. It gets exported in the gcode.

kind regards

Elco