Try this. Make a simple part - I like the 30mm calibration cube on Thingiverse. Print, oh, ten of them - I print them half-size because a 30mm cube printed flat on the bed requires channel locks to break free (and uses way too much resin). clean them, cure them, whip out your calipers and a spreadsheet and measure them X-Y-Z.

Dollars to donuts your variation is going to be 0.20mm or worse.

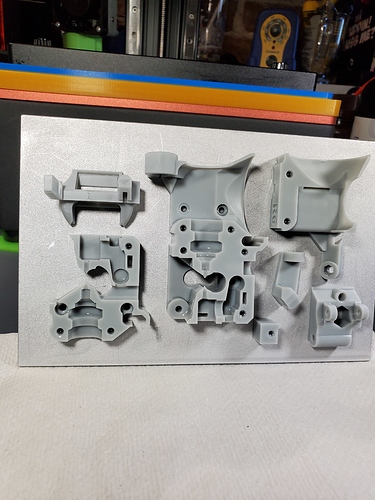

Resin printing is taffy puller engineering. You’re dealing with a material that best resembles a wet Jolly Rancher while you’re printing it (the castable wax resin is closer to “stale gummi bear”). You can work with the limitations of the process, but that starts with understanding the limitations of the process.

Youtube is full of 3d-printed “clocks” that will “run” for approximately eight ticks. That’s all they’re good for. It’s much easier to make something that looks like a machine than it is to make a machine, and if your sole purpose is to put videos on Youtube to make yourself look like a badass then yeah, you might as well print Babbage’s Analytical Engine on your Elegoo Mars 'cuz the only people who can call you on it are too busy trying to figure out why they can’t get anything to adhere to the base plate.